Ansys Mechanical

Finite Element Analysis

India

The primary challenge was to assess the structural integrity of the robotic arms under various conditions. The study needed to consider two mounting scenarios: wall-mounted and ceiling-mounted, each experiencing a downward acceleration. Addressing the complexity of these real-world conditions was essential.

IDAC diligently executed the project in a systematic manner, involving multiple steps:

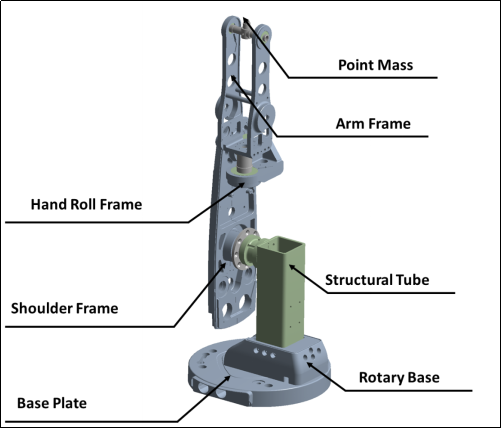

– 3D CAD Geometry Preparation: The provided geometry was meticulously prepared for Finite Element Analysis (FEA) in ANSYS Design Modeller.

– Meshing: The geometry was meshed using solid elements, ensuring accuracy in critical areas.

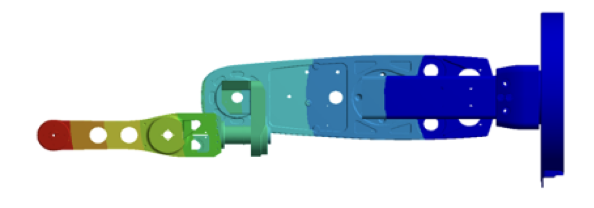

– Solution Setup and Analysis: The analysis was performed using ANSYS Professional NLS, focusing on static structural analysis for both load cases.

– Fatigue Load Case Analysis: A separate analysis was conducted to assess the structure’s fatigue resistance under different loading conditions, ensuring a comprehensive evaluation.

The study provided invaluable insights into the robot’s behavior under different mounting conditions. By simulating real-world scenarios, potential weaknesses were identified and addressed. This analysis laid the foundation for informed design improvements, enhancing the robot’s overall durability and performance.

Strength & vibration assessment and weight optimisation of the robotic arm.

The results of the structural and fatigue analysis revealed that the robot’s stress levels were well below the endurance limit, indicating a robust design. Fatigue failure was ruled out under the current loading conditions. Moreover, the low-stress regions identified through the analysis opened avenues for further weight optimization, enhancing the robot’s efficiency and longevity.