Ansys Fluent

Computational Fluid Dynamics

UAE

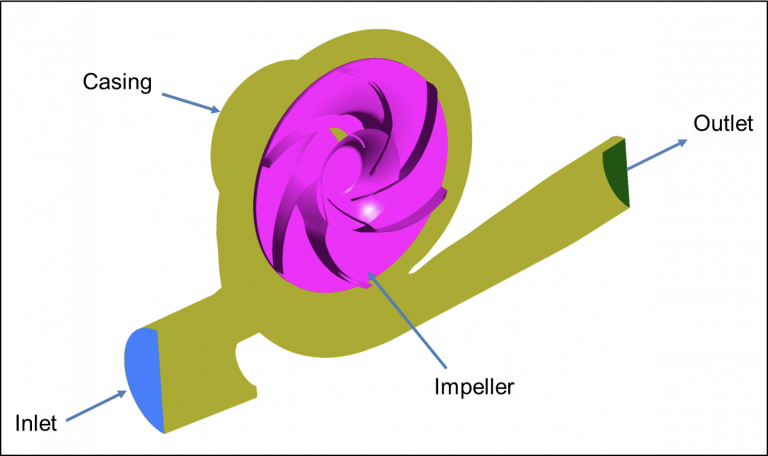

SFFECO faced the challenge of improving the efficiency of their double suction centrifugal pump while working within the constraints of the existing design. The complexity of analyzing intricate fluid dynamics and understanding flow angles added to the difficulty. Additionally, ensuring structural integrity while enhancing performance required careful balancing.

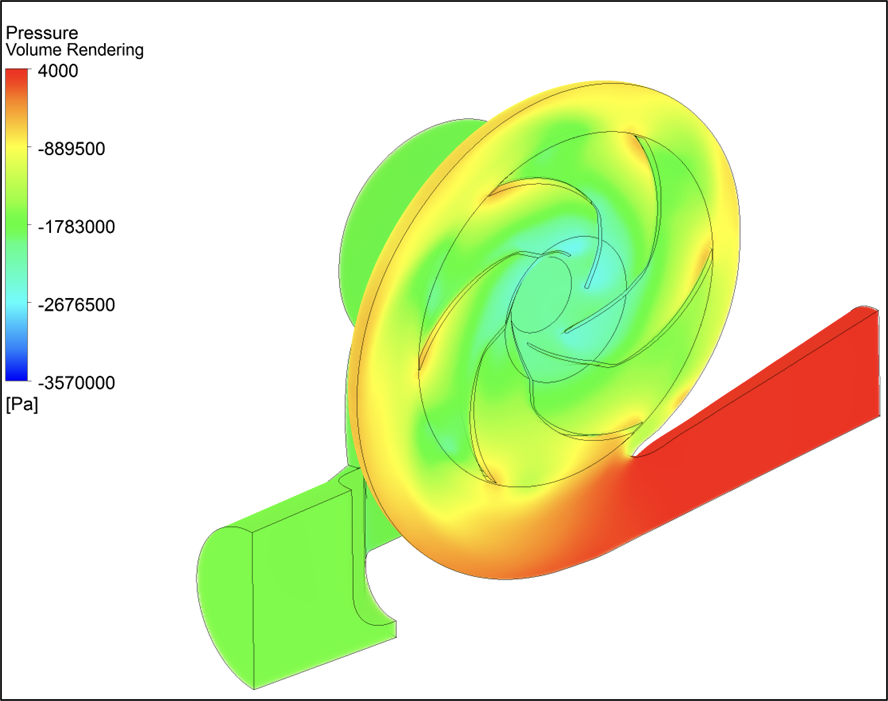

IDAC conducted a detailed steady-state Computational Fluid Dynamics (CFD) analysis, simulating multiple scenarios to assess pump efficiency. Using advanced visualization techniques, they identified key factors affecting performance, such as the impact of flow angles. The simulations provided a clear roadmap for potential design enhancements.

By leveraging CFD analysis, SFFECO gained invaluable insights into their pump’s behavior. The simulation results illuminated the effect of flow angles on efficiency, opening doors for innovative design modifications. These findings laid the groundwork for potential enhancements, showcasing the power of simulation technology in optimizing industrial equipment.

Enhanced pump efficiency and reduced cavitation.

The collaboration between SFFECO and IDAC underscored the transformative potential of simulation-driven solutions in industrial applications. The project provided critical insights into pump efficiency, equipping SFFECO with the tools to make strategic design changes. This approach not only improved performance but also set a benchmark for energy efficiency and innovation in pump design.